Poppe + Potthoff GmbH

Booth number: A101

www.poppe-potthoff.com

About us

The Poppe + Potthoff Group, with its headquarters and technology center in Werther (Westphalia, Germany), has more than 1,450 employees and long-term partners in over 50 countries. Founded in 1928, the company today has 17 plants and sales offices in 8 countries. Poppe + Potthoff is a partner of globally active companies in various technically demanding industries such as the automotive industry, mechanical engineering, marine and aerospace. The product portfolio includes common rails, precision steel tubes, high-pressure pipes, precision components, precision and industrial couplings and specially developed test systems. With innovative ‘TOPAQ’ hydrogen supply systems and components for electric vehicles, Poppe + Potthoff is contributing to an emission-free future for mobility and industry.

Address

Dammstraße 17

33824 Werther

Germany

E-mail: info@poppe-potthoff.com

Phone: +49 5203 9166-0

Internet: www.poppe-potthoff.com

Contact person:

Björn Göke

Business Development

E-mail: Bjoern.Goeke@poppe-potthoff.com

Phone: +1 586 341-0183

Products & Services

Poppe + Potthoff is a technology partner for demanding industries worldwide, including automotive, mechanical and plant engineering, marine, rail, aerospace, and medical technology.

Our portfolio comprises high-performance common rail subsystems, precision steel tubes, modular hydrogen supply systems, precision and industrial couplings, as well as complex turned parts. We also design and manufacture test benches for extreme pressure, temperature and flow conditions, customized for the validation of components in both conventional and alternative powertrains.

Our materials expertise provides the technological foundation for many of our innovations. Decades of experience in machining, testing and system integration enable us to deliver application-optimized solutions, ranging from individual components to fully integrated systems. In this way, we support our customers in meeting the challenges of decarbonization, digitalization and global competition.

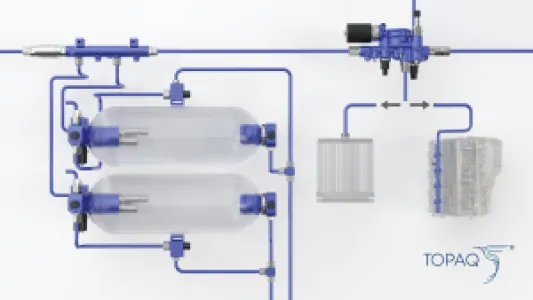

TOPAQ Hydrogen Supply System

The modular hydrogen supply system TOPAQ enables safe and efficient hydrogen flow from high-pressure storage tanks to fuel cells or hydrogen combustion engines. It combines essential components such as on-tank valves, thermal pressure relief devices, lines, manifolds (parallel charging unit), and pressure regulation units. The system can be configured to match specific application needs, making it suitable for both mobile and stationary use. Typical use cases include road and off-road vehicles, stationary hydrogen storage, and infrastructure solutions such as multi-element gas containers. With its flexible architecture and safety-focused design, TOPAQ supports the development of reliable hydrogen systems across multiple industries.

PPH2 - Material for Hydrogen Components

PPH2 is a specialized alloyed carbon steel designed for the demanding requirements of hydrogen storage and transport. Unlike austenitic stainless steel, which requires thick-walled components due to its lower strength, PPH2 offers significantly higher mechanical performance. This allows the design of thinner and lighter components without compromising pressure resistance.

A key advantage of PPH2 is its resistance to hydrogen diffusion, which is further enhanced by a proprietary PPSH heat treatment. As a result, components made from PPH2 not only reduce weight and material consumption but also lower CO₂ emissions during production.

Poppe + Potthoff uses PPH2 to manufacture high-pressure pipes and distribution rails for hydrogen systems operating at up to 700 bar. These components are EC79-certified and have passed the demanding HGV3.16 tests, confirming their suitability for modern hydrogen technologies.

Test Benches for Hydrogen Components

Poppe + Potthoff develops and supplies high-performance test benches specifically designed for testing hydrogen-carrying components under realistic load conditions. These systems enable precise testing of hydrostatic strength, burst pressure behavior, and pressure cycle resistance, supporting both in-house development and external validation processes.

The test benches allow simulation of dynamic pressure changes, temperature fluctuations, and thermal loading. Components can be tested for leak tightness under gas pressures of up to 1050 bar, even in climatic chambers. For long-term performance testing, pressures of up to 3000 bar are applied, with pressure cycle tests exceeding 100,000 load cycles to reflect real-world use over a typical vehicle lifetime.

To evaluate material performance independently of the test medium, hydraulic fluids such as oil are used. All test procedures are designed in accordance with relevant industry standards including R134 and HGV3.1, and can be adapted to meet customer-specific requirements. With these test benches, Poppe + Potthoff provides a robust platform for ensuring the safety and reliability of hydrogen components and systems.