Festo SE & Co. KG

Booth number: A101

www.festo.com

About us

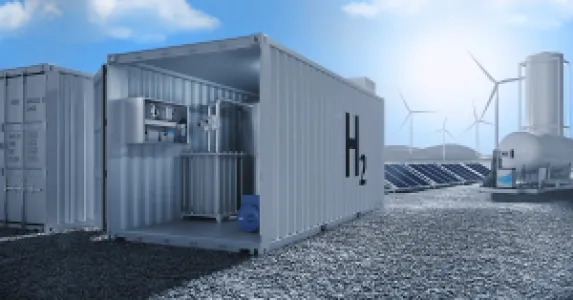

Festo is a global leader in automation technology, driving innovation across industries with smart pneumatic and electric drive solutions. We empower companies to enhance efficiency, precision, and productivity through advanced automation components and systems tailored to diverse applications. As the world shifts toward sustainable energy, Festo is actively expanding its expertise in hydrogen technology -a key growth field. Our solutions support the entire hydrogen value chain, from production and storage to handling and fuel cell integration, enabling safer and more efficient processes. By combining automation know-how with cutting-edge digitalization, we help industries unlock the full potential of hydrogen as a clean energy source. Alongside our commitment to sustainability, Festo delivers energy-efficient technologies that reduce environmental impact while maintaining high performance. We also invest in education and training to equip professionals with the skills needed for Industry 4.0 and the emerging hydrogen economy. With a global presence and customer-centric approach, Festo is your trusted partner for innovative, reliable, and future-ready automation solutions in hydrogen and beyond.

Safety for hydrogen production: Anyone who wants to produce hydrogen takes on the responsibility for doing so safely. The production of hydrogen involves risks, but these can be mitigated by using the right safety concept. Find out what the international SIL 61508 standard prescribes for hydrogen production.

Address

Ruiter Str. 82

73734 Esslingen

Germany

E-mail: bestellservice@festo.com

Phone: +49 711 3470

Internet: www.festo.com

179-187 Browns Road

Noble Park

3174 Victoria, Melbourne

Australia

E-mail: orders_au@festo.com

Phone: +61 1300 889696

Internet: www.festo.com

Unit 4, 18 Powers Road

Seven Hills

2147 Sydney, New South Wales

Australia

E-mail: orders_au@festo.com

Phone: +61 1300 889696

Internet: www.festo.com

Contact person:

Process Industry Manager - Festo Southeast Asia and Pacific Azadeh Hafezi

E-mail: azadeh.hafezi@festo.com

Products & Services

Festo is a global leader in automation technology, specializing in pneumatic and electric drive solutions, control systems, and intelligent software that optimize industrial processes. In the field of green hydrogen production, Festo applies this expertise to enable efficient, safe, and reliable generation of hydrogen using renewable energy.

Green hydrogen is produced by splitting water into hydrogen and oxygen through electrolysis powered by renewable sources. Festo provides essential automation components such as actuators, valves, and sensors that precisely control gas flow and pressure within electrolyzers, including PEM and alkaline types. Our intelligent control systems and software offer real-time monitoring and process optimization, ensuring smooth operation and enhanced safety.

Beyond supplying products, Festo offers expert training and consulting services to help customers implement and maintain hydrogen production technologies effectively. This comprehensive support fosters improved plant performance and the development of skilled professionals in the green energy sector.

With decades of experience and a commitment to sustainability, Festo empowers the green hydrogen industry by delivering innovative automation solutions that drive the energy transition. Our technologies make green hydrogen production more efficient, scalable, and accessible, contributing to a cleaner and more sustainable future.

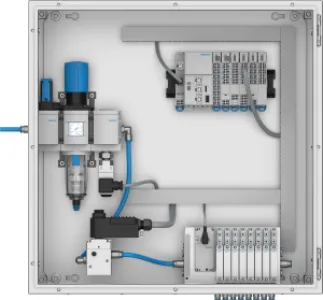

Central control cabinet solutions

A centralized control cabinet is ideal for starting and optimizing hydrogen systems. It integrates pneumatics, valves, pressure control, and electrical connections in one protected unit, simplifying installation. Benefits include pre-assembled inputs/outputs for faster assembly, multi-pin connections eliminating tubing routing, clear structure for safe installation, and time-saving pre-assembled delivery—ensuring order, protection, and efficiency.

A control cabinet brings all the important components together: the control unit, valve terminals and compressed air preparation are located in a "control centre". This creates order and reliably protects the technology – for example the pneumatic, electric and electronic components in the electrolyser – and simplifies installation

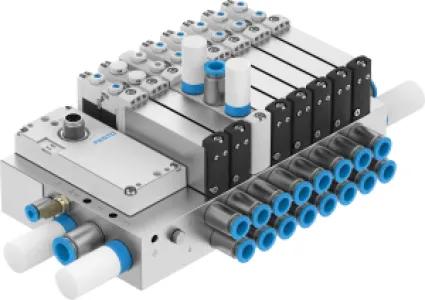

Valve terminal VTUG-EX with multi-pin or fieldbus interface

The VTUG-EX valve terminal is a flexible and compact solution certified for international standards including IEC-Ex, UL HazLoc, and CCC. It offers optional suitability for low-temperature applications and features a multi-pin plug connection with a fieldbus interface. The flexible multi-pin connection supports Sub-D or ribbon cables. Built with sturdy metal components for valves and manifold rails, it ensures durability. Fast troubleshooting is enabled through integrated LED indicators.

Remote I/O system CPX-AP-I

The CPX‑AP‑I is a flexible, decentralized, compact, and lightweight Remote I/O system designed for demanding environments. It features a high degree of protection with IP65/IP67 ratings, ensuring reliable operation even in harsh conditions. The system consists of a bus interface and at least one additional module, allowing scalable and customizable configurations.